If the heart of a brewery is akin to the brewhouse, glycol could be considered the blood.

It is what keeps your precious beer alive.

Many brewers who are starting out know of its importance – but there’s a lot more to it – and you need to get it right.

It’s about more than just deciding on the right brewery equipment. You need to consider the percentage your system needs, how much you’ll need, the type of piping you’ll use – and of course, the layout.

Here are some of the things you should consider when making these decisions.

Sizing your brewhouse chiller

When it comes to your brewery equipment, it is crucial to ensure you have the correct-sized glycol chiller – not just for your initial cellar, but also for the future.

It is better to size the chiller for future growth, as a new chiller in the future is not only costly, but your utilities might not be able to handle the electrical load.

Some clients will purchase an initial chiller – with plans to add another to help handle the load – but also as a security in case one goes down.

(As a side note, we are not glycol professionals! We use tools that are readily available, such as the nice Glycol Chiller Selection Tool from Advantage Engineering, Inc.)

In terms of chillers, we have encountered a variety of good ones out there. When making a choice, we advise our clients to think of the following:

- Indoor or outdoor chiller?

- Onboard reservoir or dedicated glycol tank?

- Can my electrical load handle it?

The above decisions will also determine where in the brewery to put these noisy and heat-producing beasts.

Who you gonna call….HVAC! Make sure you either have a licensed technician from the supplier at your fingertips - or a very skilled HVAC technician. Glycol chillers are glorified AC units so most HVAC guys will know their stuff.

Pro Tip

Glycol Piping

Once you have the chiller sized and ready to go, it is important to start thinking about how your glycol runs around the brewery.

You should make your main lines bigger than your branches to the jackets. We recommend putting in more ball valves than you need.

Each tank should have a valve right off of the main loop – for both supply and return – and then a valve before the jacket inlet, to help reduce flow if you are getting freezing on the jackets.

Remember fluid will always follow the path of least resistance. So the first vessel your glycol loop hits will get the most love – and the last will be getting the least amount of flow.

This is where the valves come in. You can reduce flow into the first vessel and work your way to the last tank, which most likely will be fully open.

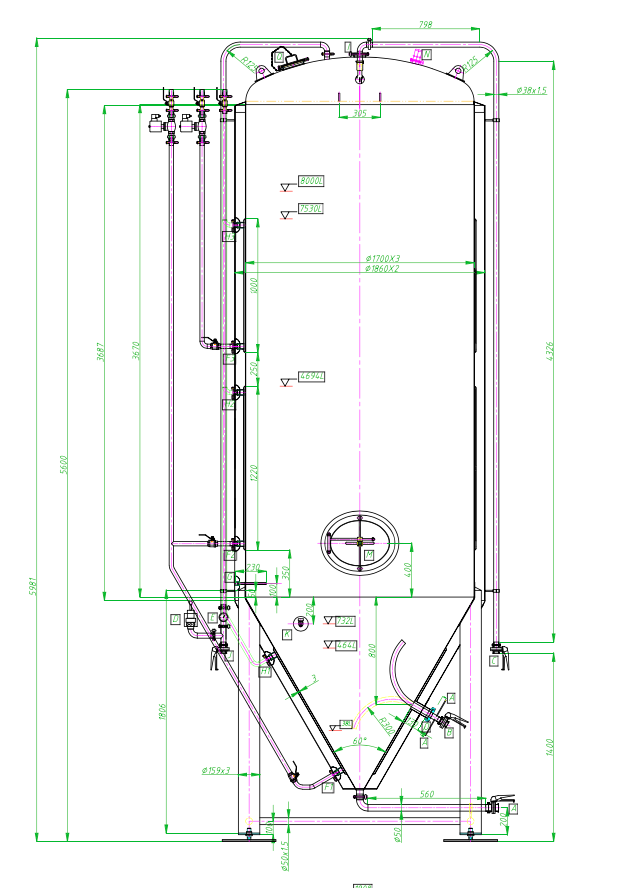

We have started supplying tanks with glycol branches with the glycol ports already done before they ship – including componentry. This saves time and money as it is very plug and play. You insulate, connect to the main loop and away you go!

Glycol Piping Material

Stainless steel is going to look the best – especially if you have an installer who can make the pipes straight. The aesthetics of straight piping running around the brewery will give a premium look even though the insulation and cladding will cover it up.

As we all know, the aesthetics in breweries are important, especially the more expensive brewpubs.

You can also choose PVC or PPR piping which works fine, but if they are not supported well they can droop down over time.

We have also had clients use soft hose, which is the most economical option but might not look the best.

After your piping is done, you need to insulate everything. This will save you money as you will have less heat escaping – and your glycol chiller will love you!

If you really want everything to pop, you can then clad the piping with either aluminum or stainless steel. This helps to match the stainless of the vessels – and it will look amazeballs!

After you have a pipe that is now insulated – and possibly cladded – you end up with a much bigger diameter than it was originally. So you should consider spacing for the piping to whip around the brewery.

Connections with your Brewery Equipment

The glycol jacket location is not standardized as well as the connection type. So make sure you specify to your manufacturer where the best place for them is.

We usually use NPT connection for the US market and BSP for everywhere else. We have used tri-clamp connections as well, but most plumbers are not familiar with them and request an adaptor.

Use that space! You can put the glycol inlets and outlets 45 degrees off of the back. This will allow you to use the empty space between the tanks and scoot them right up against a wall - or another row of vessels. You can also run the glycol piping in the insulation and terminate at the top of the vessel.

Pro Tip

We have a bleeder! In most cases, plumber’s tape will be able to handle the temperature and pressure of the glycol system. However, we now recommend clients use thread sealer (such as the one Loctite makes) for that extra security.

Double Pro Tip

Commissioning

When you commission your glycol system, first run it without glycol at around 10C for a couple of hours. This way you can check for leaks and patch up when needed. (Don’t set your chiller too low during this as the water will freeze.)

Glycol is expensive! So you do not want to be leaking money all over your brewery before you go.

When you first start sending water into your piping the goal is to flood the jackets and push out all the air in the system.

Sometimes air pockets can form and if a tank is not cooling it could be that glycol is not flowing evenly due to air pockets.

The Bespoke Difference

Glycol is an incredibly important component of your brewhouse.

This means the brewery equipment you use is important too.

But that’s not the only reason we feel you should work with us.

When you hire the Bespoke Brewing Solutions team, you get a consultant, who can walk you through the ins and outs of the entire process.

So if you’d like a teammate, as well as a supplier – get in touch.

And if you’d like to read the previous blogs in this series, we have covered other utilities including liquor and electrical requirements, steam – as well as design and layout.