You may have noticed that we are currently working on a project to revamp our series on building your brewhouse!

At Bespoke Brewing Solutions, we believe in empowering individuals in the industry through knowledge. We strive to share as much information as possible to help our brewers learn and allow the industry to thrive.

This is Part Two of our utilities section, in which we will discuss important considerations for your brewery’s water requirements.

You can check out the first blog in this series, which focuses on Electrical Requirements, here!

Volts and Hertz Brewery Water/Liquor Terminology

When I first entered the craft beer industry, I was a bit confused by the frequent mention of the term “liquor.” Phrases like “liquor mixing,” “hot liquor tank,” and “cold liquor tank” led me to believe that beer might actually be mixed with a spirit to increase its alcohol by volume (ABV).

To my relief, I discovered that in this context, “liquor” refers to water, which is actually the main building block of beer and an essential component of the brewing process.

Under pressure!

When searching for a location for your brewery, it is crucial to consider the flow rate and pressure of the main water lines entering the building, as well as how the water will be distributed to different areas of the site.

For example, if you’re trying to fill a 1000L hot liquor tank or wash down your floors using a 19mm inner diameter (ID) pipe with only 1 bar of pressure, you might find that the process takes a long time or makes little difference at all.

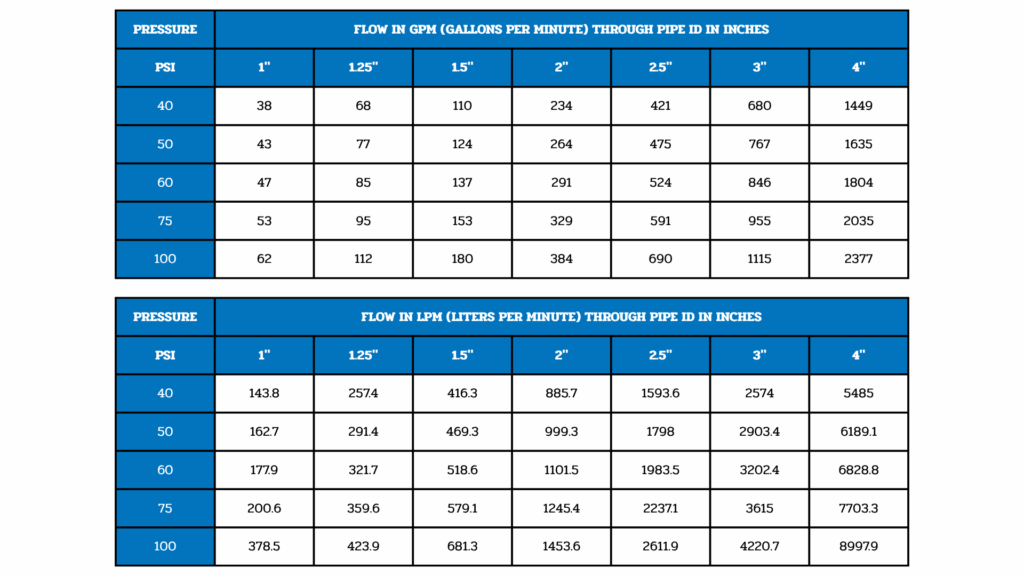

Below is a simple table that illustrates the maximum flow rates for various pipe diameters, helping you understand how much water can be transported through your main water line.

There are ways to work around this, but it’s essential to consider that other parts of the business will also need to utilize this resource. The timing of the different operations within your business is a good way to manage this.

For instance, if the brewery team is working early mornings and the kitchen or bar staff are not there until brewing is pretty much complete, then they can coexist very well.

One client in Chile installed a buffer tank equipped with a float valve that fills during the day as water is used. This is a great way to stay ahead of demand and is essential if you plan to implement a reverse osmosis (RO) system, as its output often cannot keep up with demand. If you decide to use a buffer tank, don’t forget to include a distribution pump and controls.

Water Filtration and Chemistry

Water is the foundation of your beer.

It’s surprising that more breweries don’t start with optimal water conditions. Water chemistry can be complicated, so we’ll only touch on the basics here, but we’re always ready to have a deeper discussion with our clients.

Two of the most important considerations when it comes to getting your water chemistry right are ‘hardness’ (the concentration of dissolved calcium and magnesium) and ‘alkalinity’ (the level of carbonate and bicarbonate ions). Typically, brewing water should have low to moderate levels of both hardness and alkalinity, though these requirements can vary depending on the style of beer being brewed.

The base chemistry of the water coming into your building will help determine the following:

- When considering the filtration process for your brewing water, you need to determine the best approach to prepare it for the various styles of beer you plan to brew. Some clients have invested in an RO system connected to a buffer tank specifically for brewing. In many cases, however, a small particle filter combined with an activated carbon filter will suffice. It’s essential to test your water after filtration to understand its quality and composition.

- The various types and concentrations of brewing water additives, such as salts and acids, can aid in balancing the pH and mineral composition of your water.

- Depending on the chloride content of your water, you may consider upgrading your heating tanks, such as the HLT and kettle, to more corrosion-resistant stainless steel like 316L.

Pro Tip: Most public water systems have a specifications sheet that outlines the desired water chemistry and the acceptable range they aim to achieve. You can use this information as a starting point to determine the type of filtration system you need to invest in.

John Gonzales

A Bespoke Solution

As you navigate the complexities of your brewery’s water needs, remember that both flow and composition play crucial roles in achieving the perfect brew.

Adequate water supply is essential, and optimizing its quality can elevate your brews to new heights.

If you have questions about your water management strategy, don’t hesitate to reach out. We’re here to help bring your craft beverages to life. https://bit.ly/3OBRaoD

Cheers to crafting exceptional flavors!