A picture might be worth a thousand words, but our 3D models are worth much more.

One of our primary goals this past year was to expand our team and capabilities to include 3D drafting. We are happy to share that we now have a team of 3D CAD drafters and have been able to work in more of a 3D world.

Our Process

As the creativity of brewers increases, so do the demands of the equipment to perform certain functions. From a temperature decrease before whirlpool hop additions to adding a blanket of CO2 on top of the wort for kettle souring, we strive to check all the boxes.

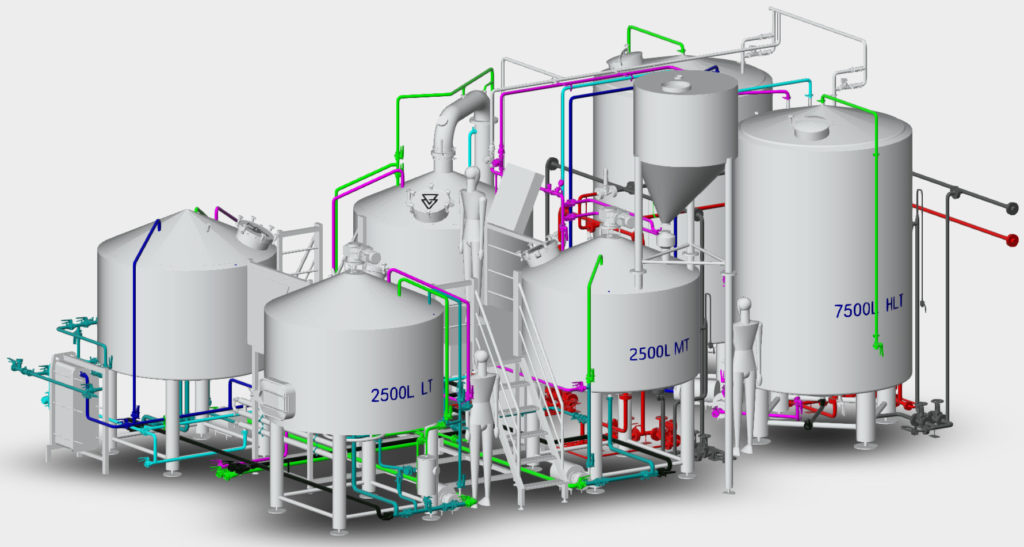

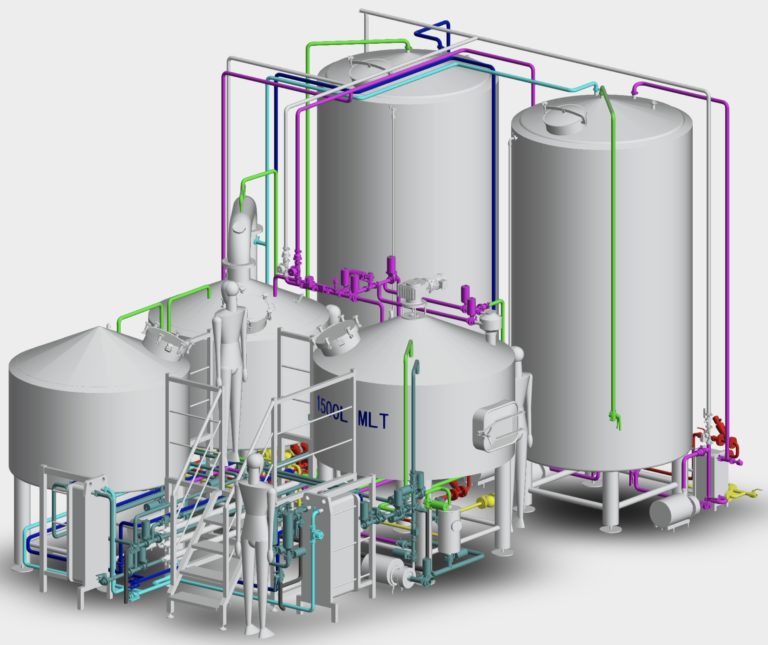

Following the Bespoke Way, we go through a detailed design process with our clients. We start with a review of their location, providing 2D drawings of the layout, equipment, and a piping and instrumentation diagram (P&ID). From there, we supply those drawings to our designers who work with the production team on an initial 3D draft of the brewery, brewhouse, or equipment.

Our team will then compare the drawings and P&ID to literally bring everything together. During this process, the lofty expectations of the sales team and clients might be reworked because of manufacturing constraints. Though it is better to be caught before the vessels are completed, as they still can be altered at that point.

We share our 3D models with our clients via a web link where they can examine the contents in a 360-degree environment. If you were a gamer in the ’90s, it’s like the first-person point of view in Doom, Quake, or Unreal!

3D models have taken our design capabilities to the next level. Here’s why:

Benefits

1. Better Visualization

2D drawings can be great for equipment with little pipework and componentry. However, once you add pipework, components, etc., 2D drawings become too convoluted to accurately paint the picture they intend to.

3D models allow anyone to easily visualize all the complexities of our design, from any perspective.

2. Alignment of Stakeholders

The weblink that we share with the client can be shared with all necessary stakeholders. This gets everyone from brewer(s) to contractors in the same field of view, ensuring everyone understands the equipment and what needs to be done for a successful installation.

Sometimes, the local team will catch a design issue concerning installation, which can save a ton of time and money if it was not caught beforehand.

3. Reduced Errors

The ability to move and see the equipment from every angle allows us to catch any design errors before production — when those errors become more costly.

We can check pipe runs and their adherence to the P&ID. Through this, we can also confirm the best locations for critical process valve placement, check and remove any dead legs, and best practice setups for the pipework.

4. Saves Time

Design changes can be made faster when working with 3D models. They are more plug-and-play as less needs to be done locally, where you are relying on tradespeople who might have a lot on the go.

Get in Touch!

We currently provide 3D models of 3 or 4 vessel brewhouses free of charge, so please reach out to our team so we can put your brewery together for you and take you for a spin.

Request a quote here. Whatever your craft beer project, we can bring it to life!